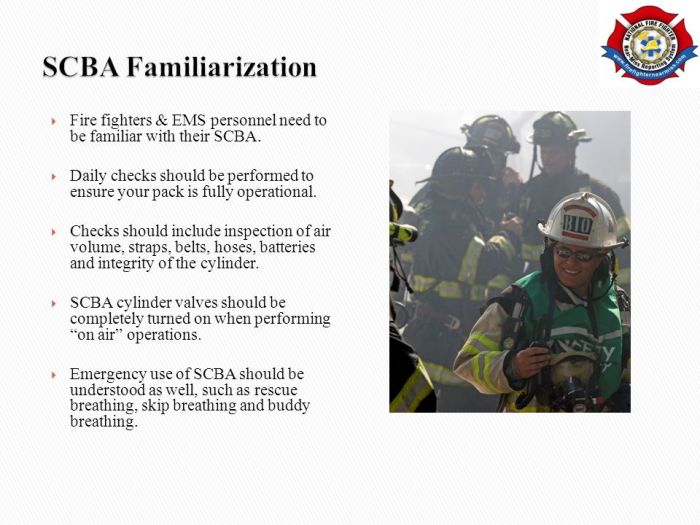

A daily/weekly inspection of scba should include – A daily/weekly inspection of SCBA is a crucial aspect of maintaining its functionality and ensuring the safety of personnel. By adhering to a regular inspection schedule, potential issues can be identified and addressed promptly, minimizing the risk of equipment failure during critical situations.

This article delves into the essential components of a comprehensive SCBA inspection, highlighting the importance of visual checks, functional testing, maintenance, and proper documentation.

Regular SCBA inspections provide several advantages. They help identify potential hazards before they escalate into major problems, reduce the likelihood of equipment failure, and enhance the overall reliability of the SCBA. Moreover, proper maintenance and documentation ensure that the equipment is in optimal condition, meeting regulatory requirements and contributing to a safer work environment.

A Daily/Weekly Inspection of SCBA

Regular inspections of self-contained breathing apparatuses (SCBAs) are crucial for ensuring the safety and reliability of these life-saving devices. A daily/weekly inspection regimen helps identify potential issues early on, preventing failures and ensuring optimal performance during emergencies.

Inspection Frequency and Scheduling

The frequency of SCBA inspections should be based on several factors, including usage, storage conditions, and applicable regulations. For SCBAs used frequently in demanding environments, daily inspections are recommended. For those used less frequently or stored in controlled conditions, weekly inspections may be sufficient.

Visual Inspection

A visual inspection involves examining the SCBA for any visible signs of damage, corrosion, or leaks. The following steps should be followed:

- Inspect the SCBA for any dents, scratches, or cracks in the cylinder, regulator, and other components.

- Check the hoses and connections for any signs of wear or damage.

- Examine the face mask for any cracks, tears, or obstructions.

Functional Inspection

A functional inspection tests the SCBA’s functionality to ensure it operates as intended. The following procedures should be performed:

- Check the pressure gauges to verify adequate air supply.

- Activate the alarms to ensure they are functioning properly.

- Simulate real-world conditions by wearing the SCBA and breathing from it for a short period.

Maintenance and Repair

During daily/weekly inspections, common maintenance tasks should be performed to ensure the SCBA is in optimal condition:

- Clean the face mask, hoses, and other components as needed.

- Lubricate moving parts, such as the regulator and valves.

- Adjust the SCBA to fit the user comfortably and securely.

Documentation and Reporting, A daily/weekly inspection of scba should include

Proper documentation of SCBA inspections is essential for tracking maintenance history and ensuring compliance with regulations. The following information should be recorded:

- Date and time of inspection

- Name of inspector

- Description of any issues identified

- Actions taken to address issues

Training and Certification

Personnel conducting SCBA inspections must be adequately trained and certified. Training programs should cover:

- Proper inspection procedures

- Identification of potential hazards

- Maintenance and repair techniques

Regular refresher training is essential to ensure proficiency and maintain a high level of safety.

Detailed FAQs: A Daily/weekly Inspection Of Scba Should Include

How often should an SCBA be inspected?

Daily/weekly inspections are recommended to ensure optimal functionality and safety.

What are the key components of a visual inspection?

Examining the SCBA for signs of damage, corrosion, or leaks, and checking for proper assembly.

Why is functional testing important?

To verify the proper operation of pressure gauges, alarms, and the breathing system, simulating real-world conditions.

What are some common maintenance tasks performed during an inspection?

Cleaning, lubricating, and adjusting components as necessary to ensure optimal performance.

Why is proper documentation essential?

To track inspection results, identify trends, and demonstrate compliance with regulations.